In the age of ecommerce and Etsy, crafters are afforded the opportunity to bring their passions to life in a way like never before. Boutique owners can now turn a collection of handmade garments into a profitable and professional brand. Dutchlabelshop offers these creative artisans a line of products to proudly and definitively identify their work as their own. Dutchlabelshop offers four types of high-quality customized labels —Brand, Size, Care, and Hang Tags— in quantities as low as 30.

Dutchlabelshop approached us to do a rebuild of their IT infrastructure. Their previous shop (also built by us) was running on Magento 1, which is approaching end of life in June 2020.

A large part of the codebase was for processing of the orders after they were placed to support the production process. We leapt at the opportunity to re-architect the codebase to make the system more robust, flexible and versatile.

We planned our work in two-week sprints and our client spent one day a week at our office to guarantee a short feedback cycle.

We had many years of customizations built into the Magento 1 installation which culminated in 75 custom-built extensions. Our first step was to sit with the client team to discuss every single extension that we used in the Magento 1 store and assess whether we need to skip it, port it or find an alternative for the Magento 2 build.

The project consists of many different but inter-related parts. In the Magento 1 webshop we had incorporated everything into Magento 1, which eventually proved not the best solution. Magento is great at what its built for but forcing it to take on responsibilities it wasn’t meant to have pushed us from time to time in awkward positions. We decided to take a service oriented architecture approach, segmenting the different but inter-related parts of the codebase into systems that do that particular job best and eventually weave it into the Magento fabric.

This meant splitting the system up in a number of distinct parts;

This case study will expand on each of them to shed some light on how we think a modern Magento 2 stack could function.

For this project we chose the Hyva theme. A theme that is super fast out of the box and easy to expand with the customization that Dutchlabelshop requires. For the customer we eventually made about 30 modules Hyva compatible and shared some them with the Hyva community.

With the old Luma theme it is very hard to keep up with the increasing demands from end customers for more speed and a better overall UX. When we have Hyva as the base for theming this becomes an easy to do task.

Accompanying the Magento 1 webshop, the customer had a Wordpress site running for all blog content. Unifying the blog content with other site content was a big wish from the clients’ content team. So we were in the market for a content management system that allowed us to:

These requirements boiled the list down to a few systems;

We had several calls with each of these and reviewed their demos thoroughly with the client’s content team to see which system best suited our requirements and preferences. We eventually decided to go with Prismic.io.

Unfortunately, there was no Magento 2 extension available to connect Prismic with Magento 2 to create a seamless experience for the content team. Since we were (and still are!) so enthousiastic about Prismic, we decided to write the extension ourselves. We also open sourced it - you can find it on our Github repo elgentos/magento2-prismicio.

You can read more about our Prismic and Magento integration here.

The core of the sales process for Dutchlabelshop is the obviously the product. Dutchlabelshop has some labels in stock, like the Made in labels. The rest of the products you have to design yourself with what we call configurators. We can separate the configurators in two categories, an uploader - were you upload an image and create the label from there, and a designer - where you design a label from some preset options that are provided. We learned a lot from these types in the Magento 1 project. The first thing is that we don’t want server-side rendering for generating the label previews. The main reason here is that server-side rendering is too slow, first and foremost because of the network latency. A client-side rendering approach gives the customer instant results when changes are made using the configurator. With client-side rendering, we don’t have to think about possible scaling issues as we would have when we would use server-side rendering. We chose React to build the configurators. For the preview we chose Fabric.js as an extra object model on top of the HTML canvas element.

For legacy browsers which do not support client-side rendering that well, we fallback to a server-side rendering client.

The base of each configurator is a JSON file that is being downloaded on page view which contains all product data. With this JSON the React application is rendering the client input fields. On each change, a new preview is generated.

In Magento 1, the source for the product data was Magento itself. When we decided to move to a service oriented architecture, we needed a place for product to originate from. The product library is that place; it contains all product types and options. Every possible option/value for products in Dutchlabelshop are in the product library. We use the product library in the various of parts of the Dutchlabelshop technical landscape, such as Magento 2, the Order Management System, and the designers & uploaders. The product library utilizes a custom-built command line tool to generate a static JSON which is compromised of several different input files, to make maintenance and overview easier.

The pricing library is similar to the product library, except that this library contains all cost and sales prices. The pricing input is generated based on a complex calculation, which takes into account a large number of variables such as label size, denier, symbol yes/no, frame yes/no, sparkling color yes/no, etcetera.

In the Magento 1 store, customers had to pick the colors that were present on the label. For the new shop, the client wanted this process to be automatic. With the help of machine learning, the colors are automatically extracted from the image. The color information is then saved in Magento and used during the production process.

Since the store is available in 16 languages, we needed a way to make sure all translations for all text is available. We created a translation microservice which parses all template files for translatable text. We then check for each piece of text whether a translation is available in all 16 languages. We have hooked this microservice into our deployment process, which will warn (or fail above a certain threshold) when missing translations are found.

The main responsibility for the middleware is to track the production of orders. Because the processes were built into the Magento 1 store, we had to port them to the middleware. This gave us a nice opportunity to revisit the processes. First, we needed to see what the current process looked like. Fortunately, the processes were already documented by Dutchlabelshop because they operate as a fully remote company.

In this case, well crafted documentation did not only help getting new employees up to speed quickly, but it also helped us to see what the current process looked like.

Next up was defining how the new process should look. To do this, we had multiple sessions with the client to visualize the entire workflow. We made a flowchart in Lucidchart. The great thing about Lucidchart is the collaboration feature. For us, this meant that we could work together with the client on the same chart at the same time.

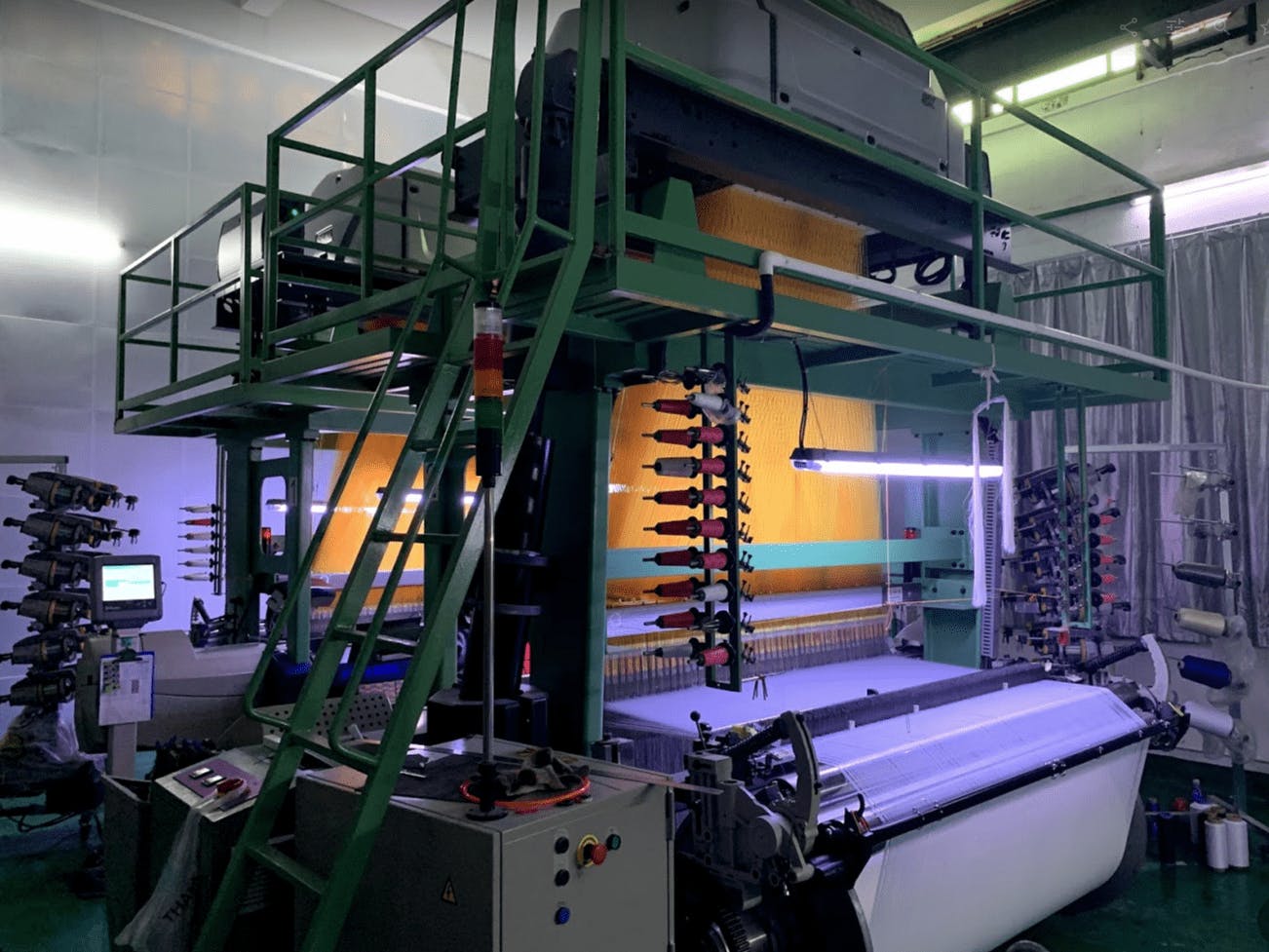

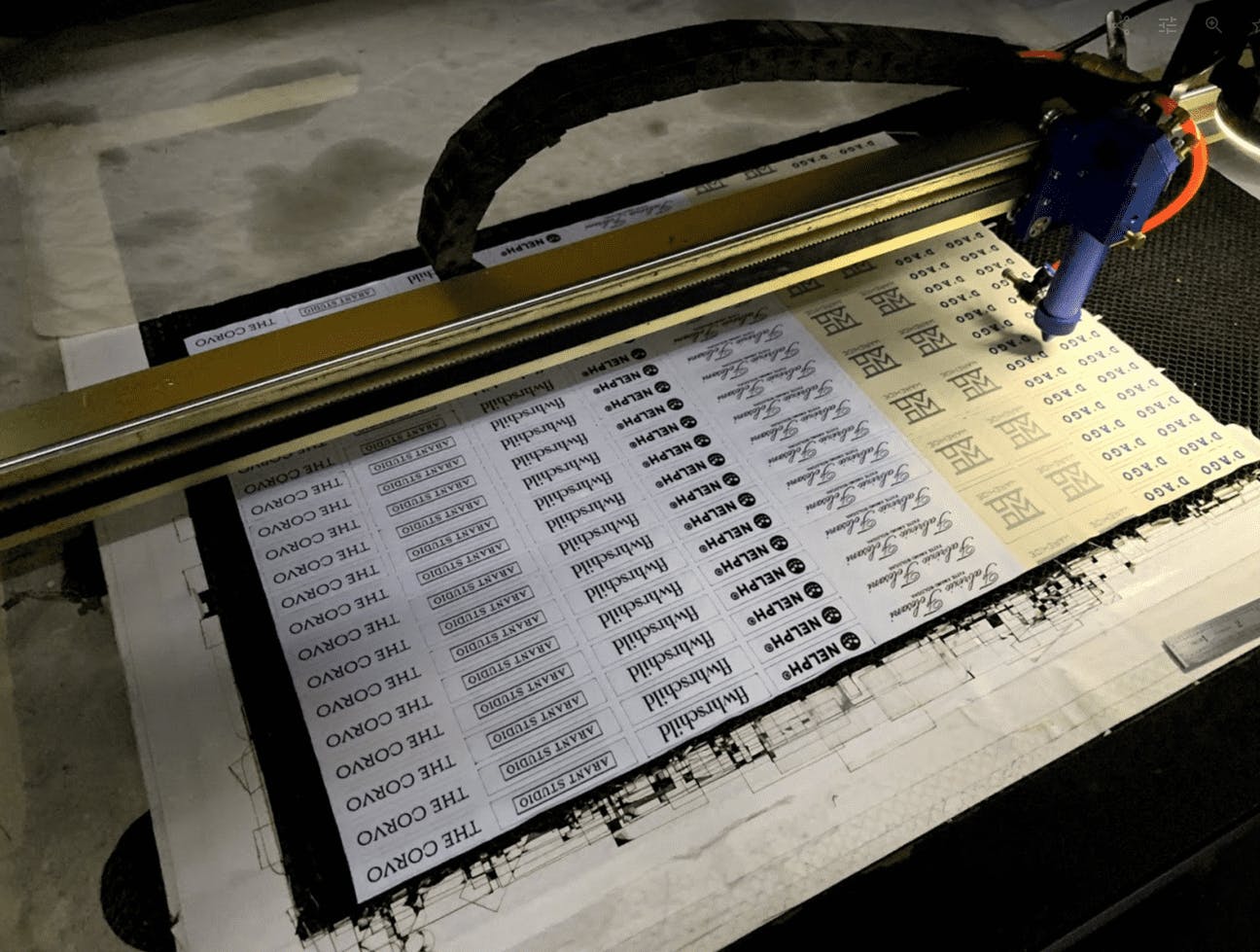

To get a grasp on the business processes with regards to the manufacturing of the labels, Peter Jaap and Jeroen visited Dutchlabelshop’s production facility.

Power loom

Color spools

Lasercutter

Our test product - elgentos logo labels

At the heart of the new shop is the custom middleware, the Order Management System or OMS for short. We built the OMS on top of Laravel, the PHP framework.

After building the flowchart and visiting the production facility, we had a clear vision about how the entire production process should flow through the application. With this in mind, we could start building the foundation of the application. For this, we broke down the application into its smallest part: the screen.

The production process consists of a number of steps. Some of these steps have one or multiple people working on it. These people only need to see the information relevant to them at that time. For this, we created screens. A screen is an overview page with all the orders that are in that step of the workflow. A screen can contain multiple actions that are different per context. A factory employee can look at the orders in his step and only focus on those orders. Orders can then be sent to the next step in the workflow or be sent back, for example, when something went wrong during production.

Order detail screen’

QA design process workflow

Upload Photo Proof workflow

Cutting preparation workflow

One of the most important features of the OMS is the permission system. In the production process, an employee is responsible for one or multiple steps. With the permission system, we can limit the employee to only see specific screens that are needed for his task. Within the workflow, permissions are connected to each step. As an extra precaution, the permission for each order is handled by the workflow. When an order goes to the next step, the workflow automatically checks what permission is connected to that step. This permission is then added to the order, so the right employee sees it.

In addition to showing/hiding entire orders for employees, we also have the opportunity to hide specific pieces of information. For example, a factory worker can not see any client or financial information but only sees the information relevant for the task.

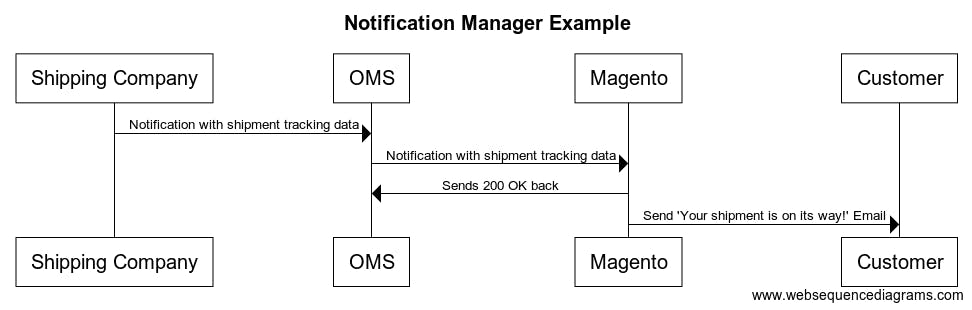

When an order goes through the entire production process, Magento needs to continually be updated. For this, we wrote the notification manager. On the OMS side, every (whitelisted) action triggers a notification to Magento. Based on this, Magento picks up the notification and checks if it needs to perform an action. For example, it’s possible to order a product that has a photoproof. When the customer does this and the order reaches the photoproof stage of the production process, OMS sends a notification to Magento. This notification contains all the data neccesary for a mail to be sent to the customer notifying him of the photoproof.

The notification manager is also used with shipping notifications. OMS is responsible for creating the shipments and sending them to the fulfillment services. The fulfillment services relay the shipment tracking data to OMS, which in turn moves the order along the workflow and sends the shipment tracking data to Magento via the notification manager. Magento then sends shipment tracking data to the customer via email until the shipment is delivered.

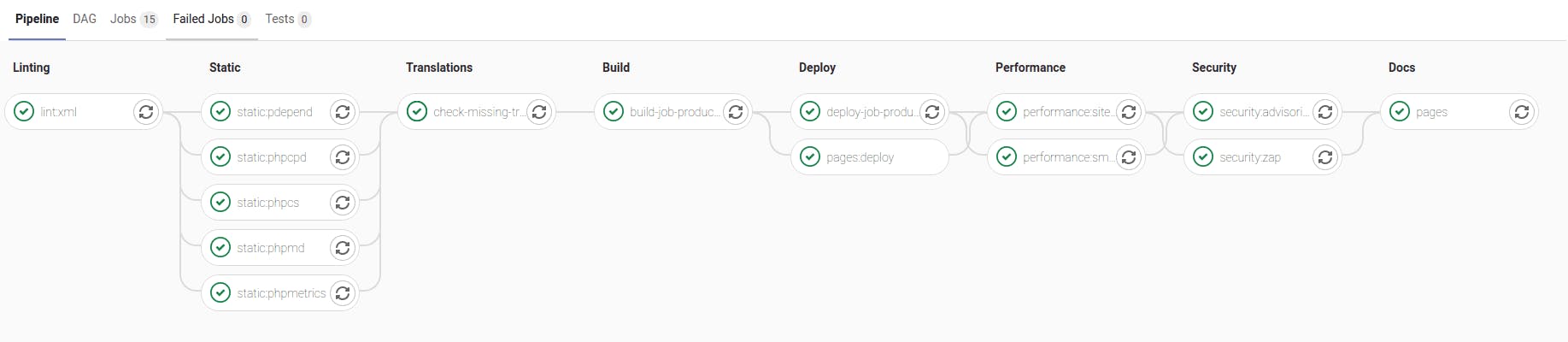

We needed to make sure all these moving parts fit in together like they suppose to. We also needed a way to keep code quality up to par and to warn us when something is off. To achieve this, we have implemented a CI/CD pipeline in Gitlab to automate several checks and build processes for us.

CI/CD pipeline

This pipeline produces a small website with documentation about code quality, code complexity, security checks, translation checks, etcetera for our developers to review periodically.